The Thermal Grease Your PC Begged For

© Iceberg Thermal

We tested two thermal pastes from Iceberg Thermal: FuzeIce and FuzeIce Plus. Note that these thermal pastes can still be found in retail under the names BlackIce and BlackIce Plus, respectively. This is due to the fact that the manufacturer decided to change the name of the line. The effectiveness of these thermal pastes was compared with each other; in addition, the sample of test participants was expanded to include several popular thermal pastes on the Russian market.

Passport characteristics

| Manufacturer | Iceberg Thermal | |

|---|---|---|

| Name | FuzeIce | FuzeIce Plus |

| Thermal conductivity coefficient, W/(m K) | 11.25 | thirteen |

| Viscosity, poise | 56000* | 60000* |

| Density, g/cm³ | 2.6 | |

| Specific electrical resistance, Ohm m | 1.8×10 12 | |

| Storage temperature, °C, min./max. | +5/+250 | |

| Operating temperature, °C, min./max. | -50/+200 | |

| Packing, g | 3.5 or 7 | |

* Here, apparently, an overestimation by two orders of magnitude, should be 560 and 600 .

Description

The manufacturer’s website for thermal pastes has a detailed description, high-quality images, and a link to a PDF file with characteristics. For thermal pastes, packaging options of 3.5 and 7 g are indicated. Judging by the images, they differ in the degree of filling of the syringe and, of course, in packaging. We had 3.5 g options for testing. Syringes with thermal paste were packed in strong tubes made of thick cardboard.

The tubes are separated into two unequal parts, which, until opened, are held by a sticker that performs informational and protective functions. The label, designed in corporate style, has the name, product description, main characteristics, barcodes, etc. Special curly liners on the inside at the ends of the tube keep the thermal paste syringe in the center, at least until it is full.

If the plunger of the syringe is pressed in a few millimeters, then the syringe in the tube is already loose. However, there is no special need to store the syringe in the tube after opening the package. The tube is useful in the household, for example, for storing drills.

There is only a syringe in the tube, there are no additional accessories and documentation – napkins, spatula applicators, instructions, etc. – no.

But the syringe itself is unusual. It has a special flattened shape. In its upper part there are stops for the middle and index fingers, and the lower part is closed with a cap with secure fixation. But the most important feature of the syringe is its spout, which works as an applicator for convenient and quick application of thermal paste on the processor cover in a thin and even layer. This is achieved due to the fact that the outlet on the spout is a narrow slot 12 mm wide, on one side of which there is a bevel that helps to hold the syringe at the desired angle, and on the other side there are teeth that distribute the thermal paste over the entire width of the slot of the spout.

Using such an applicator, the cover of a modern processor for a consumer PC (we do not take AMD Ryzen Threadripper into account) can be covered with thermal paste in 3-4 movements, which is much faster than leveling it with a spatula.

The color and consistency of FuzeIce and FuzeIce Plus thermal paste are about the same, the first property can be described as light gray, and the second as moderately viscous.

Testing

In order not to be limited to comparing only the above thermal pastes, we expanded the sample for testing with a number of thermal pastes, the declared characteristics of which are presented in the table below.

| Name | KPT-8 | Arctic MX-4 | Arctic MX-5 | Prolimatech PK-3 | Thermal Grizzly Kryonaut |

|---|---|---|---|---|---|

| Thermal conductivity coefficient, W/(m K) | 0.7-0.8 | 8.5 | ??? | 11.2 | 12.5 |

| Viscosity, poise | 90-150 | 870 | 550 | ??? | 1300-1700 |

| Density, g/cm³ | 2.6—3.0 | 2.5 | 3.2 | 2.7 | 3.7 |

| Operating temperature, °C, min./max. | -60/+200 | -50/+150 | -40/+180 | ??? | -200/+350 |

Prolimatech PK-3 thermal paste is new to us, others have already participated in a large comparison test , and we compared the relatively new Arctic MX-5 with Arctic MX-4 during this test .

To test thermal interfaces, we used a stand that included an Intel Core i9-7980XE processor based on the Skylake-X (HCC) core, installed on an ASRock X299 Taichi motherboard , as well as an active cooler with a flat copper sole, six heat pipes and aluminum cooling fins . To simulate operation in difficult conditions, the cooler fan ran at a slightly lower speed, which was achieved by reducing the PWM duty cycle to 70%, which corresponded to a rotation speed of about 1550 rpm. In order to better equalize the temperature, in addition to the air conditioning fan, keeping the temperature as low as 24 °C, we used a household fan running at minimum speed and directed from a distance of about 1.3 m to the stand. To take into account the inevitable fluctuations in the temperature of the air surrounding the stand, for each measurement we subtracted the actual air temperature from the processor temperature and added 24. In the tests, all cores of the Intel Core i9-7980XE processor worked at a fixed frequency of 3.2 GHz (multiplier 32). To set the frequency, the A-Tuning program of the motherboard manufacturer was used. After applying the thermal interface and installing the cooler, the stand warmed up with the maximum processor load using the powerMax test (using the AVX command system). Then, for 30 seconds of work in the same mode, the average temperatures of 18 processor cores, the temperature in the room, and the fan speed on the cooler were determined. The average of the average values for the cores was taken as the processor temperature. The processor consumption was determined by measuring the current strength at the additional 12 V connector on the mat. board.

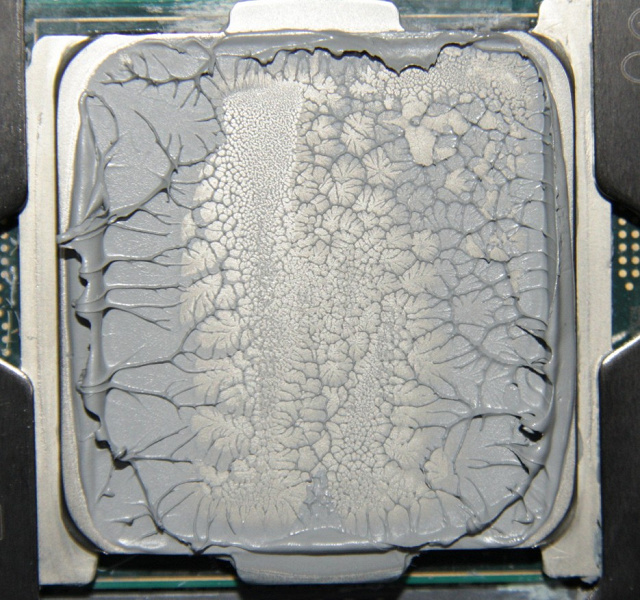

Despite the convenient applicator of Iceberg Thermal thermal pastes, we applied all thermal pastes in the form of a large drop in the center of the processor cover. Note that, according to our assessment, the fastening of the used cooler provided a very strong and uniform pressure of the sole to the processor cover. In addition to the pressure, for a better distribution of the thermal paste, we displaced the sole of the cooler with a clamp several times after the fixing screws were screwed in, and only then finally tightened them. The nature of the distribution of thermal paste on the sole of the cooler removed after testing and on the processor cover indicated that the thermal interface was indeed distributed fairly evenly and in a thin layer. When the sole was torn off the processor cover, the layer was still destroyed, and, depending on the viscosity of the thermal paste, structures with rollers (low viscosity) or gaps (high viscosity) were formed. Note that the cover of this processor is not perfectly flat, but slightly convex, so in the center there was an area of tight contact, where the thermal paste layer was of the minimum thickness, while towards the edges the thickness of the thermal paste layer increased.

For example, let’s demonstrate the distribution of Iceberg Thermal FuzeIce Plus thermal paste on an Intel Core i9-7980XE processor:

And on the sole of the heat sink:

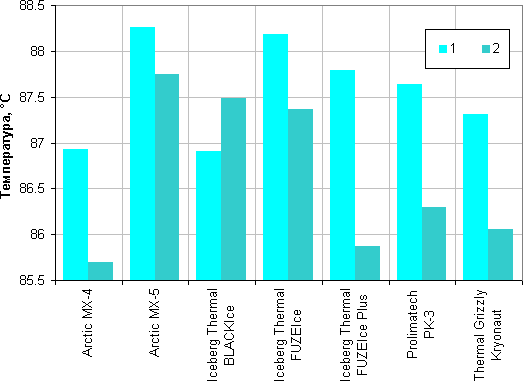

Testing was performed in two runs. The diagram below shows the processor temperature values obtained in the first (1) and second (2) runs.

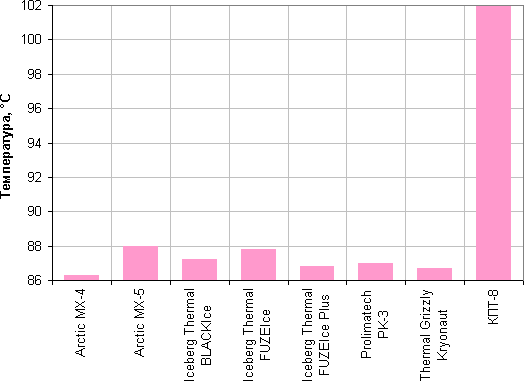

The spread of values in the case of all thermal pastes, except for KPT-8, within one run did not actually exceed plus or minus one degree. In the second run, in most cases, the temperature was lower, which can be explained by partial grinding of the surfaces and an increase in the area of tight contact. However, there is no significant correlation between the two runs, which allows us to conclude that the efficiency of all thermal greases (except for KPT-8) is high and the test conditions, due to errors and variations in conditions, do not allow us to identify differences between them. Further, we will use the temperature values averaged over two runs and, for clarity, we will include the result for KPT-8:

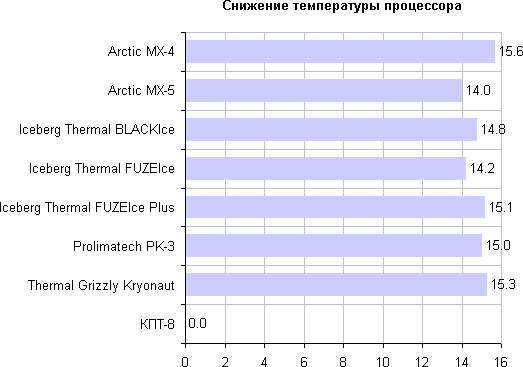

For a more visual representation of the results, we chose the processor temperature obtained using KPT-8 as a starting point. The diagram below shows how much the processor temperature (under our test conditions, of course) is lower when using other thermal interfaces than KPT-8 (higher is better):

It is clearly seen that the effectiveness of seven thermal pastes (recall that Iceberg Thermal FuzeIce and BlackIce are, in fact, the same thermal paste) is approximately the same, and in this case they allow to reduce the processor temperature by 14-15 degrees compared to CPT- eight.

In fact, in the case of the KPT-8, under these conditions, the processor was already overheating and alternately dropped the frequencies by cores, and hence the consumption, that is, it is no longer correct to compare only by temperature. Knowing the processor consumption, let’s recalculate the result into the thermal resistance of the cooler (higher is worse):

However, the essence has not changed depending on the presentation form: seven thermal pastes are approximately the same, and KPT-8 is much worse.

findings

Our testing has shown that the performance of Iceberg Thermal FuzeIce and FuzeIce Plus is on par with the best thermal pastes available on the market. A distinctive feature of Iceberg Thermal thermal pastes is a strong packaging with tamper-evident control, as well as a very convenient applicator on a syringe, which facilitates and speeds up the process of uniform application of thermal paste to the processor.

In conclusion, we suggest watching our video review of the comparison of Iceberg Thermal FuzeIce and FuzeIce Plus thermal interfaces:

Our video review of the comparison of Iceberg Thermal FuzeIce and FuzeIce Plus thermal interfaces can also be viewed at iXBT.video