Passport characteristics, scope of delivery and price

| Manufacturer | cooler master |

|---|---|

| Family | Master Liquid |

| Model | MasterLiquid PL360 Flux |

| Model Code | MLY-D36M-A23PZ-R |

| Type of cooling system | liquid closed type pre-filled non-expandable for processor |

| Compatibility | motherboards with processor sockets: Intel: LGA1700 , LGA1200, LGA2066, LGA2011-v3, LGA2011, LGA1151, LGA1150, LGA1155, LGA1156; AMD: AM4, AM3+, AM3, AM2+, AM2, FM2+, FM2, FM1, TR4 |

| Fan type | axial (axial), 3 pcs. |

| Fan Model | PL Flux (FA12025L12LPT) |

| Fan power | motor: 12 V, 0.3 A, 4-pin connector (common, power, rotation sensor, PWM control); backlight: 5V, 3-pin header (common, data, power) |

| Fan dimensions | 120×120×25 |

| Fan speed | 650-2300 rpm |

| Fan performance | maximum 123 m³/h (72.37 ft³/min) |

| Fan static pressure | maximum 29 Pa (2.96 mm w.c.) |

| Fan noise level | 32 dBA maximum |

| Fan bearing | ORBS |

| Fan life | over 160,000 hours |

| Radiator dimensions | 394×120×27 mm |

| Radiator material | aluminum |

| flexible hose material | there is no data |

| water pump | integrated with a heat sink, two chambers in a water block |

| Pump dimensions (L×W×H) | 89×75×40 mm |

| Pump power | motor: 3-pin connector (common, power, rotation sensor, 12 V, 6 W); backlight: 3-pin connector (addressable LED backlight) |

| Pump noise level | 15 dBA maximum |

| Pump Mean Time to Failure (MTTF) | over 210,000 hours |

| Heat sink material | copper |

| Heat sink thermal interface | thermal paste MasterGel Pro in a syringe |

| Peculiarities |

|

| Contents of delivery |

|

| Retail offers |

Description

The Cooler Master MasterLiquid PL360 Flux liquid cooling system is supplied in a box of medium thickness corrugated cardboard. On the outer planes of the box, the product itself is shown in color, as well as the main features and technical characteristics are listed, there are also drawings of the pump and radiator with the main dimensions. Some of the images are varnished. The inscriptions are mostly in English, but some of them are duplicated in several languages, including Russian. A papier-mâché mold, polyethylene foam padding and plastic bags are used to protect and distribute parts. The sole of the heat sink is protected by a plastic film. Small fasteners are packaged according to the type in signed bags, which is very convenient.

Inside the box is what is listed in the table above:

The installation manual is an accordion book of good printing quality. The information is mostly presented in the form of pictures and does not need to be translated, although there is an important note in several languages, including Russian. The company’s website has a description of the system, PDF files with a description of the system and installation instructions, and Cooler Master MasterPlus software for backlight control.

The system is sealed, primed and ready to use. The pump is integrated into one unit with a heat sink. The manufacturer indicates that the water block is two-chamber, apparently the pump chamber is on top, and the heat sink chamber is on the bottom. The heat sink is made of copper. Its central rectangular part (48×41 mm), directly adjacent to the processor cover, protrudes 4 mm relative to the flange with mounting holes. The heat sink planes are ground, but not polished. The working surface is slightly, about 0.1 mm, convex towards the center.

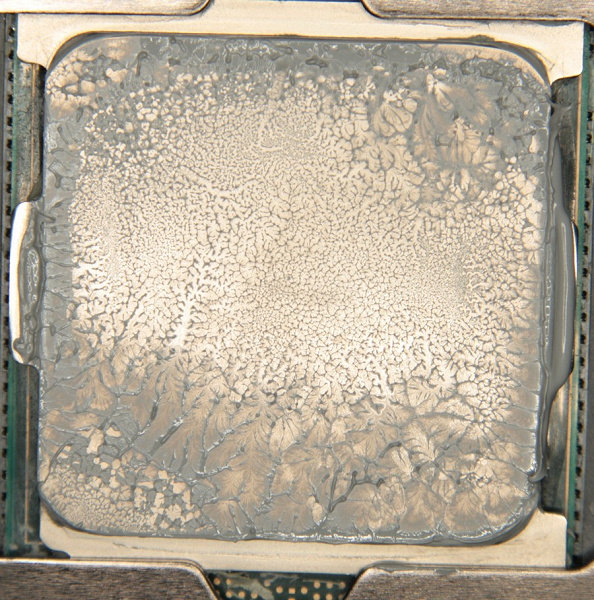

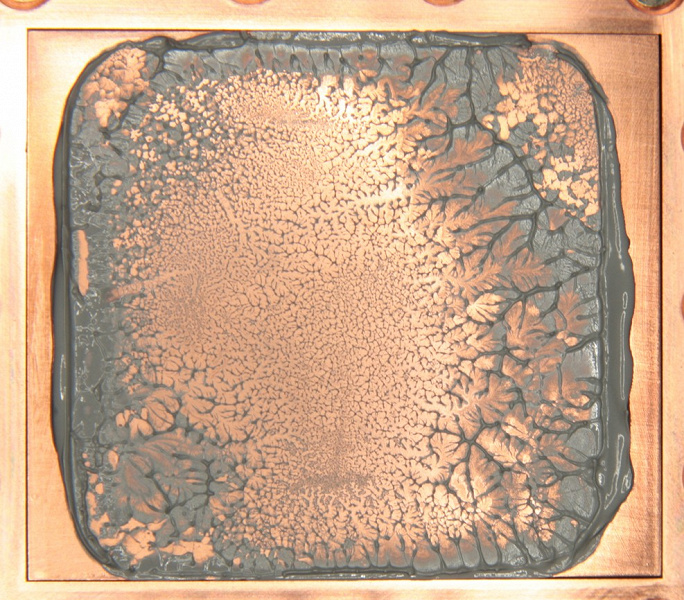

Thermal paste in a small syringe, which, of course, is less convenient than a pre-applied layer. A complete supply of thermal paste should be enough for two times in the case of processors with a small cover area and at economical consumption. The tests used no less high-quality thermal paste from another manufacturer. Looking ahead, we will demonstrate the distribution of thermal paste after all tests are completed. On an Intel Core i9-7980XE processor:

And on the sole of the pump:

It can be seen that the thermal paste was distributed in a thin layer over the entire area of the processor cover, and its excess was squeezed out of the edges. The dense contact area is located approximately in the center and has a large area. Note that the cover of this processor itself is slightly convex towards the center. (The thermal paste distribution, of course, changed slightly when the processor and pump were separated.)

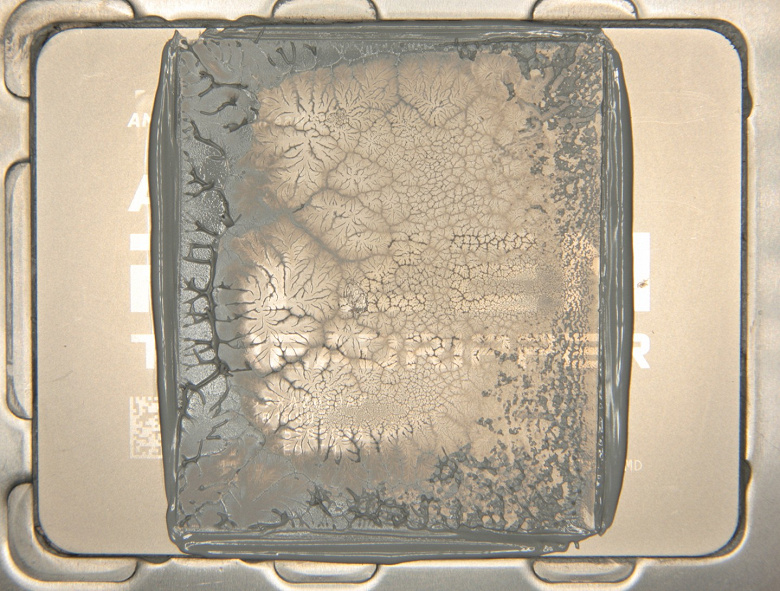

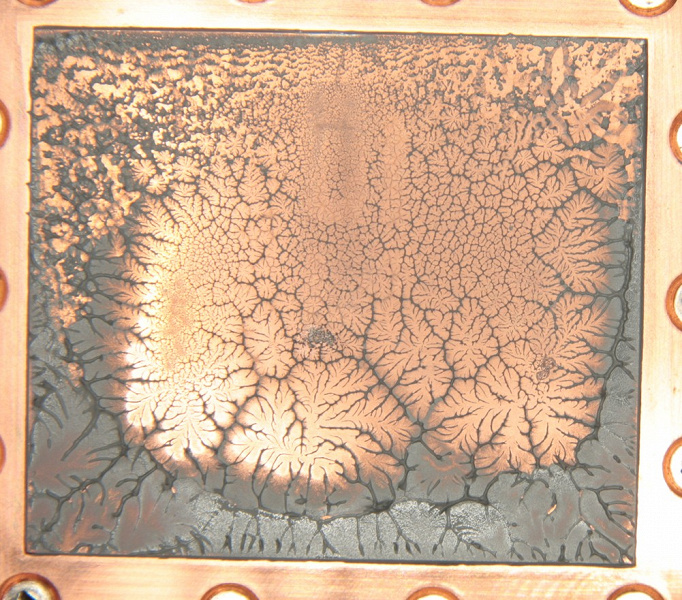

In the case of an AMD Ryzen Threadripper 2990WX processor. On processor:

On the sole of the heat sink:

In this case, the working area of the heat sink is much smaller than the area of the processor cover. The tight contact patch is large, but it obviously does not cover all four dies of this processor.

The pump housing is made of hard black plastic. A cover of complex design is fixed on top of the pump. Its main parts are the outer casing made of black plastic, the inner annular diffuser made of white translucent plastic and the disk with the logo on top.

The disk can be rotated around its center without restrictions, which allows you to set the logo in the correct orientation. Under the lid of the pump are several addressable RGB LEDs that illuminate the ring diffuser and the logo outline on the lid. These LEDs are externally controlled via a 3-wire interface. The diameter of the cylindrical part of the pump housing at the bottom is 75 mm. Pump height 40 mm. The length of the power cable from the pump is 30 cm, the backlight cable is also 30 cm. These cables are enclosed in a slippery braided sheath. According to the legend, the sheath reduces aerodynamic drag, but taking into account the thickness of the flat three/four-wire cable inside this sheath and its outer diameter, we strongly doubt the veracity of this legend. However, the shell will allow you to maintain a single style of interior decoration of the case. The hoses are resilient, but relatively flexible, they are enclosed in a slippery plastic braid, the outer diameter of the braided hoses is approximately 13 mm. The length of the hoses along the flexible part is 36 cm (not short). The L-shaped fittings at the inlet to the pump rotate, which makes it easy to install the system.

The radiator is made of aluminum and has a relatively durable matte black finish on the outside. Radiator dimensions – 394 × 119 × 27 mm. The maximum thickness of the heatsink with attached fans is 58mm. Note that the fans can be attached to the heatsink without using a screwdriver, as the screws have large knurled heads (and they have threaded holes for attaching the heatsink to the case panel through the fans). The complete system (without backlight controller and cables to it) with fasteners for Threadripper has a mass of 1668 g. Fasteners are made mainly of hardened steel and have a durable galvanized coating. The frame on the back of the motherboard is made of durable plastic and equipped with steel threaded sockets.

The fan frame is made of durable black plastic.

Vibration-isolating rubber pads are glued to the eyes in the corners of the fan frame. In the uncompressed state, they protrude by about 0.5 mm relative to the plane of the frame. As conceived by the developers, this should provide vibration decoupling of the fan from the attachment point. However, if we estimate the ratio of the fan mass to the stiffness of the linings, it becomes clear that the resonant frequency of the structure is very high, that is, there can be practically no vibration decoupling. In addition, the sockets where the mounting screws are screwed are part of the fan frame, so the vibration from the fan through the screws is transmitted without interference to the radiator. As a result, such an eye design can only be considered as a fan design element.

The impeller blades are enclosed in a ring, which can improve the efficiency of the fan. The fan impeller is made of white translucent plastic. On the fan stator, eight ARGB LEDs are placed around the circumference, which illuminate the impeller from the inside.

The fan has a four-pin connector (common, power, rotation sensor and PWM control) at the end of the 30 cm power cable. A separate cable of the same length with a three-pin connector is used for the backlight. These cables are also encased in a slippery braided sheath. The 23 cm fan power splitter also has a sheath.

The complete controller controls only the operation of the backlight. The controller is magnetized by the bottom plane, on which there are rubber feet, which facilitates its installation in the computer case.

The detachable power cable (45 cm long) of the controller is connected using a SATA power connector, which is much more convenient than a peripheral connector (“Molex type”). The controller is equipped with three connectors for connecting devices with addressable lighting. Only one connector is used to connect this system, since the connection of the pump and three fans is carried out using one cable with five output connectors (from the input to the splitter 22 cm and 33 cm for each branch). Docked connectors on the backlight cables can be fixed with special plastic brackets included in the kit. If the motherboard or another backlight controller has a standard three-pin connector for connecting an ARGB backlight, then the controller from the kit can be omitted. If you connect the controller to the system board via a USB cable (61 cm long), then you can control the backlight using the MasterPlus program. Without connecting to a PC, the default mode is active, as the fans and the pump are highlighted in the video below:

Cooler Master MasterLiquid PL360 Flux comes with a 5 year warranty.

Testing

A full description of the testing methodology is given in the corresponding article ” Testing methodology for processor coolers of the 2020 sample “. For the main load test, the powerMax (AVX) program was used, all cores of the Intel Core i9-7980XE processor worked at a fixed frequency of 3.2 GHz (multiplier 32).

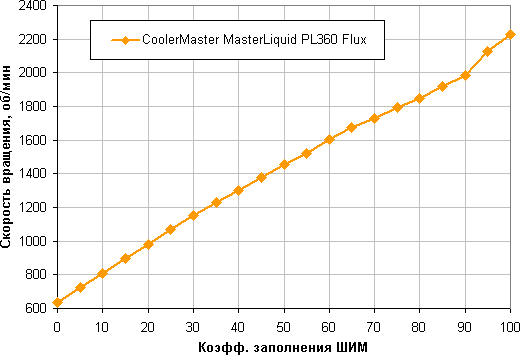

Determination of the dependence of the cooler fan speed on the PWM duty cycle and / or supply voltage

An excellent result is a monotonous increase in the rotation speed when the duty cycle is changed from 0% to 100%, the rotation speed adjustment range is wide. When the fill factor (SC) drops to 0, the fans do not stop. This may be of value if the user wants to create a hybrid cooling system that operates fully or partially in passive mode at low load.

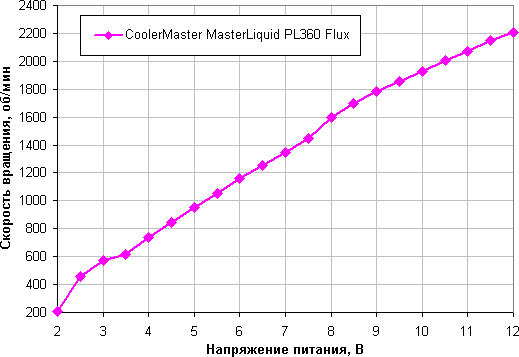

Adjusting with voltage allows you to get a stable rotation in a slightly wider range. The fans stop when the voltage drops to 1.8-1.9 V and start from 2.1-2.2 V. It is quite acceptable to connect the fans to a source with a voltage of 5 V.

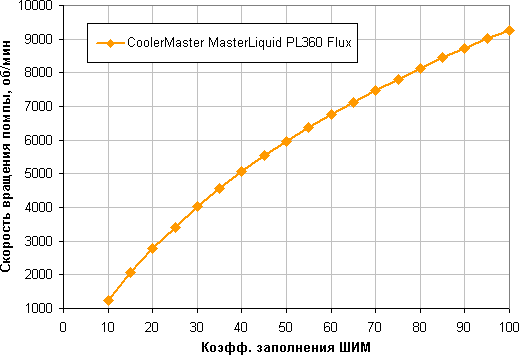

The rotation speed of the pump can also be adjusted using PWM and supply voltage. Here are the corresponding graphs.

The pump stops at a short circuit of 9% and starts at a short circuit of 10% In the case of voltage regulation, it stops at 3.9 and starts at 4.0 V. It is also permissible to connect the pump to 5 V. Note that, most likely, the actual rotation speed of the pump is two times lower than that obtained by counting the tachometer pulses.

Determination of the dependence of the temperature of the processor at its full load on the speed of rotation of the cooler fans

In the case of tests under load and when measuring the noise level, the rotational speed of the fans and the pump was changed using PWM when the short circuit changed in the range from 100% to 0% in 5% steps.

In this test, our 140W TDP processor does not overheat (at 24 degrees Ambient) at fan speeds achieved with short circuit down to 20%, corresponding to about 980 fan rpm and 2800 pump rpm.

Determining the noise level depending on the speed of rotation of the cooler fans

The noise level from this cooling system is not very high over the entire range of fan speeds. The first two points on the graph above (fans less than 800 RPM) correspond to conditions where the pump has not yet turned on. It depends, of course, on individual characteristics and other factors, but somewhere from 40 dBA and above, the noise is, from our point of view, very high for a desktop system; from 35 to 40 dBA, the noise level is classified as tolerable; below 35 dBA, the noise from the cooling system will not stand out much against the background of typical non-noisy PC components – case fans, fans on the power supply and on the video card, as well as hard drives; and somewhere below 25 dBA the cooler can be called conditionally silent. The background level was equal to 16.0 dBA (conditional value, which shows the sound level meter). The pump is very quiet:

From a noise reduction point of view, it is not necessary to reduce the pump speed, but when high performance is not required, it can still be done to extend the life of the pump.

Plotting the dependence of the real maximum power on the noise level

Let’s try to get away from the conditions of the test bench (24 degrees of ambient air) to more realistic scenarios. Let’s say that the temperature of the air taken in by the cooling system fans can rise to 44 ° C (this is a realistic scenario, for example, when the LSS is set to blow out of the case in which a powerful video card is running), but the temperature of the processor under maximum load does not want to increase above 80 °C Restricting ourselves to these conditions, let’s plot the dependence of the real maximum power (denoted as P max (previously we used the designation Max. TDP )), consumed by the processor, on the noise level ( details are described in the methodology ):

Taking 25 dBA as a conditional noiselessness criterion, we get the approximate maximum power of processors corresponding to this level. This is about 240 W for an Intel Core i9-7980XE processor. If you do not pay attention to the noise level, then the power limits can be increased somewhere up to 345 watts. Let us clarify once again that in harsh conditions of blowing the radiator with air heated to 44 degrees, when the air temperature drops, the indicated power limits for silent operation and maximum power increase.

Comparison with other LSS when cooling the Intel Core i9-7980XE processor

Using this link , you can calculate the power limits for other boundary conditions (air temperature and maximum processor temperature) and compare this system with several other LSSs tested using the same methodology (the list is updated). It can be seen that this LSS in conditions of low productivity has average characteristics, but at high power this system is one of the best, that is, it cools better and makes less noise.

Testing on an AMD Ryzen Threadripper Processor

We also decided to find out how this system will cope with the cooling of the Ryzen Threadripper 2990WX processor , the maximum consumption of which reaches 335 watts. In the test, all processor cores worked at a fixed frequency of 3.5 GHz (multiplier 35). The powerMax program was used as a load test (using the AVX command system).

The dependence of the temperature of the AMD Ryzen Threadripper 2990WX processor at full load on the fan speed:

In fact, the 2990WX processor overheats at 24 degrees of ambient air at fan speeds achieved at short circuits below 25% (below 1090 fan rpm) – the core frequency is already starting to decrease. At the beginning of the test, there is an abnormal change in temperature. Apparently, we failed to distribute the thermal paste in a thin enough layer, and only after warming up, its excess was squeezed out from under the sole of the pump, which increased the cooling efficiency.

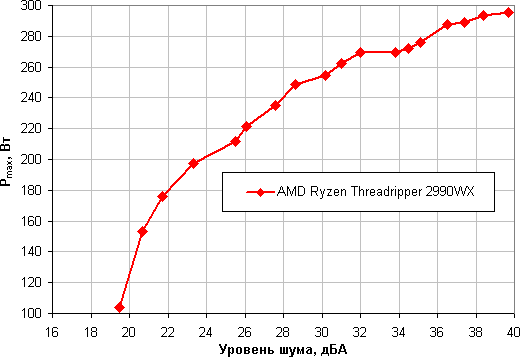

Restricting ourselves to the above conditions, let’s plot the dependence of the real maximum power (denoted as P max ) consumed by the processor on the noise level already in the case of the AMD Ryzen Threadripper 2990WX:

Taking 25 dBA as a conditional noiselessness criterion, we get that the approximate maximum power of a processor corresponding to this level is about 210 W. If you do not pay attention to the noise level, then the power limit can be increased somewhere up to 300 watts. Once again, we will clarify: this is in harsh conditions of blowing the radiator with air heated to 44 degrees. As the air temperature drops, the specified power limits for quiet operation and maximum power increase. The result for the LSS, which is obviously not optimized for AMD Ryzen Threadripper, is good, but worse than in the case of the Intel Core i9-7980XE processor. This can be explained by the fact that the heat sink area (more precisely, its active part) does not cover the entire area on which the AMD Ryzen Threadripper processor chips are placed.

Comparison with other coolers and coolers when cooling AMD Ryzen Threadripper 2990WX

You can use this link to calculate the power limits for other boundary conditions (air temperature and maximum processor temperature) and compare this system with several others tested in the same way (the list of systems grows) with an AMD Ryzen Threadripper 2990WX processor. The result is similar – at medium and high power, this LSS is one of the best among those tested by us by the time this article was published.

findings

Based on the Cooler Master MasterLiquid PL360 Flux liquid cooling system, you can create a conditionally silent computer (noise level 25 dBA or less) equipped with an Intel Core i9-7980XE (Intel LGA2066, Skylake-X (HCC)) processor, if the processor consumption is under maximum load will not exceed 240 W, and the temperature inside the case will not rise above 44 °C. Processor such as AMD Ryzen Threadripper 2990WX, this coolant can silently cool if the processor consumption does not exceed 210W. With lower cooling air temperatures and/or less stringent noise requirements, the power limits can in all cases be increased. In the area of medium and high performance, this LSS is one of the most efficient in its class among those tested in our laboratory. Fans of modding will appreciate the multi-color and multi-zone static or dynamic lighting of fans and pumps, which has a standard three-pin connection. Fan and pump lighting can be controlled using the included controller and MasterPlus software. Among other advantages, we note the good workmanship, the braiding of cables and hoses (at least helping to maintain a uniform design style for the inside of the computer), connecting the controller to the SATA power connector, convenient fan mounting and rather long hoses.