Passport characteristics, scope of delivery and price

| Manufacturer | cooler master |

|---|---|

| Family | Master Liquid |

| Model | ML360 Sub zero |

| Model code | MLZ-D36M-A19PK-12 |

| Type of cooling system | liquid closed type pre-filled non-expandable for processor |

| Compatibility | motherboards with Intel LGA1200 processor sockets |

| Fan type | axial (axial), 3 pcs. |

| Fan model | SF120R (FA12025L12LPT) |

| Fan power | 12 V, 0.3 A, 4-pin connector (common, power, rotation sensor, PWM control) |

| Fan dimensions | 120×120×25 mm |

| Fan speed | 650-1900 rpm |

| Fan performance | maximum 100 m³/h (59 ft³/min) |

| Fan static pressure | maximum 19.6 Pa (2.0 mm w.c.) |

| Fan noise level | 8-26 dBA |

| Fan life | 160 000 h |

| Radiator dimensions | 394×120×27mm |

| Radiator material | aluminum |

| flexible hose material | there is no data |

| water pump | separate |

| Pump dimensions | 57×57×92 mm |

| Pump power | 12V, 1.0A (Maximum 13.8W), 3-pin connector (common, power, rotation sensor) |

| Pump noise level | < 35 dBA |

| Pump Mean Time to Failure (MTTF) | 198 000 h |

| water block | copper heat sink + thermoelectric converter (52×52 mm) with liquid cooling |

| Heat sink thermal interface | applied thermal paste |

| Water block power | 12V Mini-Fit connector 8 pins |

| Connection | fans and pump: into a splitter (4 outputs) that connects to the 4(3)-pin (rotation sensor only) connector for the CPU cooler on the motherboard and to the SATA power connector from the PSU (only 12V power and common); water block: to the PCI-E power connector (8 pins) from the PSU (12 V power supply and common) and to the cable with a Micro-USB connector (control and management), which connects to the internal USB 2.0 connector on the motherboard. |

| Peculiarities |

|

| Contents of delivery |

|

| Retail offers |

Description

The Cooler Master MasterLiquid ML360 Sub-zero liquid cooling system is supplied in a large box of medium thickness corrugated cardboard. On the cardboard shell of the box, decorated in corporate colors, the product itself is depicted, as well as the main features and technical characteristics are listed, there are drawings of the water block, pump and radiator with the main dimensions. The inscriptions are mostly in English, but some of them are duplicated in several languages, including Russian. A mold and a polyethylene foam pad are used to protect and distribute the parts. Accessories are packaged in plastic bags and packed in a cardboard box. The sole of the heat sink is protected by a casing made of hard plastic.

Inside the box is what is listed in the table above:

The installation manual is an accordion book of good printing quality. The information is mainly presented in the form of pictures and does not need translation. The company’s website contains a description of the system, PDF files with a description of the system, installation instructions and answers to frequently asked questions, as well as links to the required software.

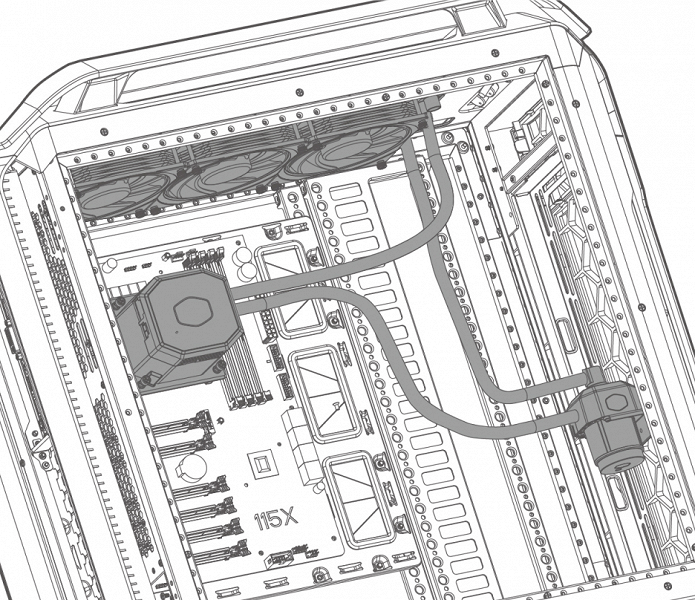

The system is sealed, primed and ready to use. The pump of this system is made in the form of a separate unit. It is assumed that it will be installed on regular places for mounting fans of size 120 mm, for which a bracket with threaded holes and a rubber gasket on the landing plane is fixed to the pump, and two M5 screws are included in the delivery package.

The length of the power cable from the pump is 31 cm.

The waterblock is large.

Despite the dimensions, the water block is placed between the heatsinks of the voltage regulator unit and does not interfere with the installation of memory modules, except that the outgoing hoses will prevent the installation of modules with very high heatsinks. Note that the orientation of the water block on the motherboard is determined by the skirt configuration and cannot be changed.

The water block includes a sealing skirt ( D ), a copper heat sink ( C ), a thermoelectric converter (Peltier element – B ), a liquid cooling module for this converter and an electronic control module ( A ). The diagram from the manufacturer’s website explains the device of the water block:

Power is supplied to the Peltier element via two wires from the control board. In turn, this board has an 8-pin PCI-E power connector, which is supplied with 12 V from the PC power supply. The interface for interaction between the control board and the PC and software is USB, implemented as a Micro-USB socket. A thin layer of thermal paste is applied to the plane of the heat sink directly adjacent to the processor cover.

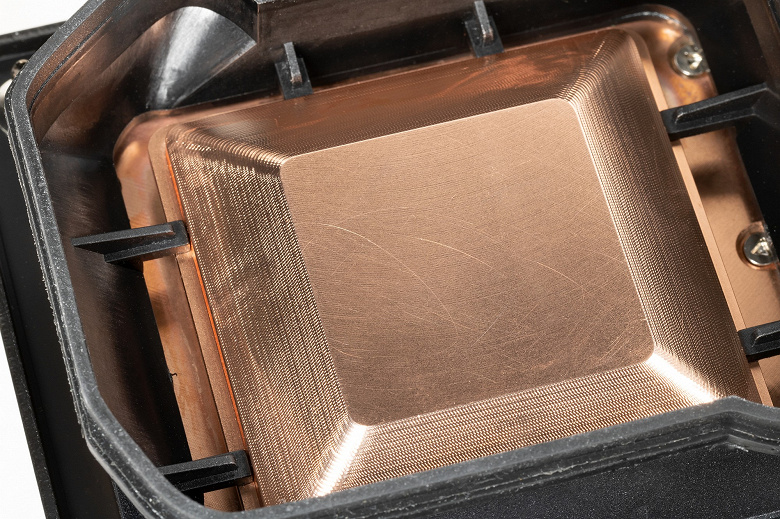

The surface of this contact area is ground, slightly polished and almost perfectly flat.

The dimensions of the contact area are 31×31 mm. Note that the tests used high-quality thermal paste from another manufacturer. Looking ahead, we will demonstrate the distribution of thermal paste after all tests are completed. On an Intel Core i9-11900K processor:

And on the sole of the pump:

On an Intel Core i9-10900K processor:

And again on the sole of the pump after the test with this processor:

It can be seen that in both cases, the thermal paste was distributed in a very thin layer over the entire area of the processor cover, and its excess was squeezed out of the edges.

The hoses connecting the water block, pump and radiator in a ring are elastic, but relatively flexible, they are sheathed in slippery plastic, the outer diameter of the braided hoses is approximately 12 mm. Length of hoses by segments including fittings: 36 cm (water block – pump), 39 cm (pump – radiator), 33.5 cm (radiator – water block). The length of the hoses is enough to accommodate the system components in a typical case as recommended by the manufacturer: the pump is on the front wall, the radiator is on the top.

The radiator is made of aluminum and has a relatively durable matte black finish on the outside.

Note that the fans can be attached to the heatsink without using a screwdriver, as the screws have large knurled heads (and they have threaded holes for attaching the heatsink to the chassis panel through the fans). The complete system with fasteners has a weight of 2476 g. Fasteners are made mainly of hardened steel and have a durable galvanized coating. The frame on the back of the motherboard is made of durable plastic and equipped with steel threaded sockets.

The fan frame is made of durable black plastic.

Vibration-isolating rubber pads are glued to the eyes in the corners of the fan frame. In the uncompressed state, they protrude by about 0.5 mm relative to the plane of the frame. As conceived by the developers, this should provide vibration decoupling of the fan from the attachment point. However, if we estimate the ratio of the fan mass to the stiffness of the linings, it becomes clear that the resonant frequency of the structure is very high, that is, there can be practically no vibration decoupling. In addition, the sockets where the mounting screws are screwed are part of the fan frame, so the vibration from the fan through the screws is transmitted without interference to the radiator. As a result, such an eye design can only be considered as a fan design element.

The impeller blades are enclosed in a ring, which can improve the efficiency of the fan. The fan has a four-pin connector (common, power, rotation sensor and PWM control) at the end of a 30 cm power cable. This cable is encased in a slippery braided sheath. According to the legend, the sheath reduces aerodynamic drag, but taking into account the thickness of the flat three/four-wire cable inside this sheath and its outer diameter, we strongly doubt the veracity of this legend. However, the shell will allow you to maintain a single style of interior decoration of the case. The fan and pump power splitter also has a shell. The length of each of the four splitter branches is 30 cm, and another branch of the same length extends from the pump connector with a connector for connecting to the processor cooler connector, which allows you to monitor the speed of the pump. According to the manufacturer’s idea, the fans and the pump always run from 12 V at maximum speed, and the fan speed is not monitored. However, nothing prevents the user from connecting the fans the way he wants. This is more difficult to do with a pump because the connector on its power cable is different from a typical fan connector.

Brief description of Intel Cryo Cooling technology

The use of the Peltier element in processor coolers has a very long history, but has not received mass distribution. Perhaps the turn has come to try to revive it at a new level of development of cooling systems. The essence of the operation of the Peltier element is that when electrical energy is supplied, one side of this element begins to cool and the other to heat up, that is, thermal energy is pumped from one side to the other. By placing the cold side on the processor, you can improve the heat transfer from the processor to the cooler due to the increased temperature difference. True, in this case, the overall load on the cooling system will increase, since it will have to remove both heat from the processor and the energy (already in thermal form) that the Peltier element itself consumes. But this will be the second stage after cooling the processor itself, so the cooler developer will have more space in the truest sense of the word to solve this problem most effectively. Since the Peltier element can provide cooling below the ambient temperature, there is a risk of the temperature dropping below the dew point and condensation. This danger is eliminated by monitoring the temperature and humidity of the surrounding air (which is sufficient to determine the dew point under current conditions) and timely limiting the temperature drop. Also, in order to restrict air access to the cold surfaces of the cooler (and therefore, in principle, to limit the possible condensation to only a tiny amount of moisture in a small volume of air), the lower part of the water block is surrounded by a skirt with an elastic rubber border, which is tightly pressed against the printed circuit board around the processor socket.

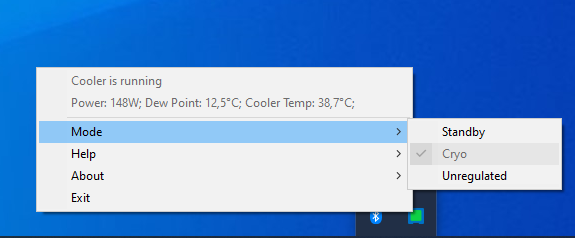

The operation of the thermoelectric converter of the LSS water block Cooler Master MasterLiquid ML360 Sub-zero is controlled by Intel Cryo Cooling Technology software . After launching this program, an icon appears in the tray giving access to a short menu:

Three modes of operation:

- The thermoelectric converter is not switched on and the cooling system works without its participation. At the same time, the indicator on the water block slowly flashes blue.

- In the normal and recommended operating modes, the thermoelectric converter operates in the optimal mode, from the point of view of developers, providing processor cooling with minimal power consumption and preventing condensation. At the same time, the indicator on the water block slowly flashes green.

- In unregulated mode, the Peltier element operates at maximum power, which provides the best cooling for the processor, but leads to increased consumption and the risk of condensation. At the same time, the indicator on the water block quickly flashes purple.

A steady red glow of the indicator on the water block indicates an abnormal situation, including the lack of communication between the software and the water block control board.

We add that Cooler Master recommends using the settings in the BIOS or the Intel XTU program to overclock the processor, which, among other things, allows you to overclock the processor in automatic mode, taking into account the allowable processor heating under stress. The second method will certainly be appreciated by those users who do not want to understand the numerous settings and their relationship with processor heating and its performance.

Testing

A full description of the testing methodology is given in the corresponding article ” Testing methodology for processor coolers of the 2020 sample “. Since the system under test is only compatible with processors installed in the LGA1200 socket, we had to make adjustments to the methodology. We used an Asus ROG Maximus XIII Hero motherboard, as well as Intel Core i9-11900K and Intel Core i9-10900K processors . For the load test, the powerMax (AVX) program was used, all cores of the first processor worked at a fixed frequency of 4.8 GHz (multiplier 48), and the second at 4.7 GHz (multiplier 47). The operating modes of the processors are set using the Intel XTU program . Maximum consumption for additional connectors 12 V per mat. board in the first case was 224 watts, in the second – 218 watts.

For comparison, we present some of the results obtained when testing the Cooler Master MasterLiquid ML360 Illusion liquid cooling system. This LSS has a radiator of the same dimensions, also with three 120 mm fans. We will need a comparison, since we do not have the data obtained during testing on the above processors. At the same time, MasterLiquid ML360 Illusion is tested according to the standard method and compared with other LSS, which makes it possible to perform a two-stage and at least qualitative cross-comparison of the tested LSS with others tested by our standard method.

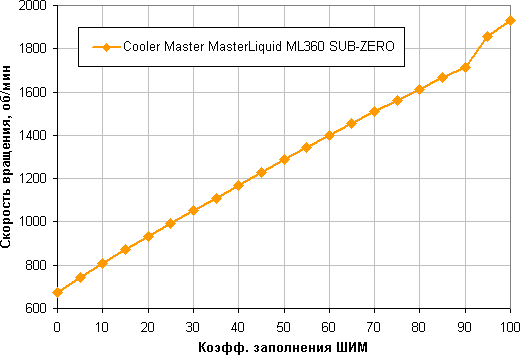

Determination of the dependence of the cooler fan speed on the PWM duty cycle and / or supply voltage

An excellent result is a monotonous increase in the rotation speed when the duty cycle is changed from 0% to 100%, the rotation speed adjustment range is wide. When the fill factor (SC) drops to 0, the fans do not stop. This may be of value if the user wants to create a hybrid cooling system that operates fully or partially in passive mode at low load.

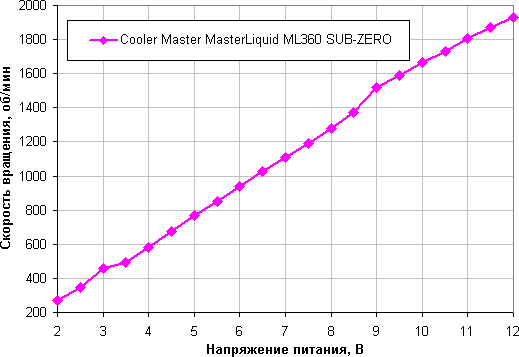

Adjustment with voltage allows you to get a stable rotation in a wider range. The fans stop when the voltage drops to 1.8 V and start from 2.2-2.9 V. Thus, it is quite acceptable to connect the fans to a 5 V source.

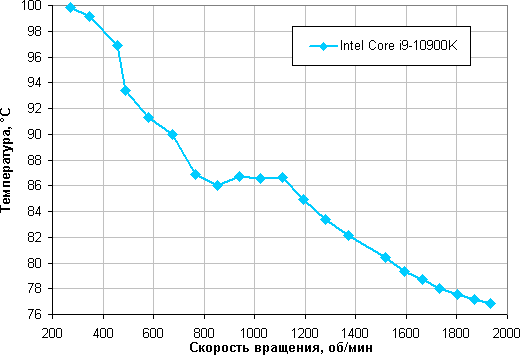

Determination of the dependence of the temperature of the processor at its full load on the speed of rotation of the cooler fans

Since there is no regular regulation of the rotation speed of the fans and the pump, in order not to limit ourselves to one measurement, we regulated the indicated speeds by changing the supply voltage of the pump and fans. The absence of overheating and operation at the set frequencies in both cases were observed up to 1180-1190 rpm of the fans inclusive (this is 7.5 V).

Determining the noise level depending on the speed of rotation of the cooler fans

The noise level from this cooling system is not very high over the entire range of fan and pump speeds. The absence of a monotonous increase in the noise level as the fan speed increases is due to the anomalous behavior of the pump: at some fan speeds, the noise from the pump can increase dramatically. It depends, of course, on individual characteristics and other factors, but somewhere from 40 dBA and above, the noise is, from our point of view, very high for a desktop system; from 35 to 40 dBA, the noise level is classified as tolerable; below 35 dBA, the noise from the cooling system will not stand out much against the background of typical non-noisy PC components – case fans, fans on the power supply and on the video card, as well as hard drives; and somewhere below 25 dBA the cooler can be called conditionally silent.

The rotation speed of the pump can be adjusted by changing the supply voltage:

The pump stops when the voltage drops to 4.6 V and starts from 5.7 V. It turns out that it is better not to connect the pump to 5 V. The noise level only from the pump when it is running at maximum speed is high, so create a very quiet or conditional A silent system based on this LSS is not possible, but it is possible to reduce the noise level to an acceptable level by reducing the supply voltage of the pump and fans – but only to a level that maintains sufficient cooling capacity. Fans can also be controlled using PWM.

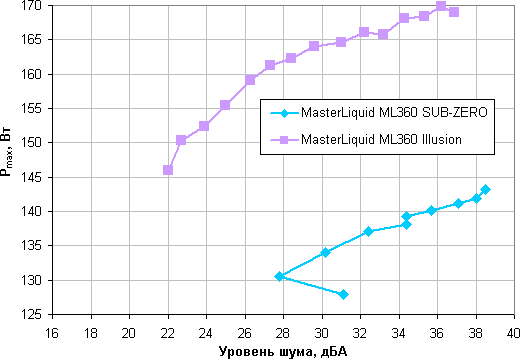

Plotting the dependence of the real maximum power on the noise level

Let’s try to get away from the conditions of the test bench to more realistic scenarios. Let’s say that the temperature of the air taken in by the cooling system fans can rise to 44 ° C, but the temperature of the processor under maximum load does not want to be raised above 80 ° C. Restricting ourselves to these conditions, we plot the dependence of the real maximum power (denoted as P max (we used the designation Max. TDP earlier)), consumed by the processor, on the noise level ( details are described in the methodology ). For comparison, here are the data obtained when testing the Cooler Master MasterLiquid ML360 Illusion liquid cooling system under the same conditions (same processors, etc.):

For the tested Cooler Master MasterLiquid ML360 Sub-zero, we used data from the range in which there was no overheating of processors and a decrease in their operating frequencies. It can be seen that this LSS with a thermoelectric converter, firstly, does not provide conditionally noiseless (noise level 25 dBA and below) operation under maximum load even in almost ideal conditions; and secondly, in terms of efficiency, a simple LSS with a radiator of the same dimensions loses – the difference in power dissipation at the same noise level reaches more than 20 watts.

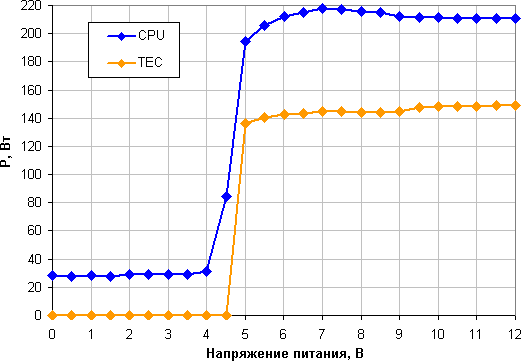

From our point of view, if we do not take into account the high noise from the pump, then the main problem is too much power consumed by the Peltier element. To illustrate this, here is a graph of the power consumed by the Intel Core i9-10900K processor ( CPU ) and the Peltier element ( TEC ) depending on the supply voltage of the pump and fans:

(At 4.5 V, the pump stopped, so the LSS went into emergency mode and the Peltier element turned off, and the processor went into economy mode due to lack of cooling.) In the operating range – from 12 to 5 V – the consumption of the Peltier element alone was 140 – 150 watts, and the processor – 194-218 watts. It turns out that, ceteris paribus, a LSS with such a thermoelectric converter should additionally dissipate these same 140-150 W, which is a lot against the background of processor consumption. In principle, a heat sink with a Peltier element has a lower temperature, and a coolant, on the contrary, has an increased temperature, while both factors increase the overall efficiency (after all, the difference with MasterLiquid ML360 Illusion is not 140-150 W, but only 20-30 W), but This is not enough. Perhaps by equipping such a water block with a more powerful and quiet pump, a radiator with a larger area, as well as hoses with a larger diameter, the cooling capacity can be increased so that the heat generated by the Peltier element itself will minimally affect the efficiency of the system, and the benefits of a thermoelectrically cooled heat sink will be noticeable. Also, in theory, such a heat sink can positively affect the operation of the processor in the case of very short-term heavy loads, for which the heat capacity of the cold heat sink is enough to work off, but it is hardly possible to check this with tests, and even more so feel it in real use of a PC.

findings

The Cooler Master MasterLiquid ML360 Sub-zero liquid cooling system is a high-tech device with a thermoelectric converter and a software and hardware component for monitoring and controlling its operation. Unfortunately, the potential of the Peltier element in this particular case could not be realized, since this LSS works less efficiently than a conventional LSS with similar parameters. This result is partly due to the high level of noise from the pump. Also, the disadvantages that reduce the practical value of the MasterLiquid ML360 Sub-zero include the lack of a regular ability to adjust the speed of rotation of the fans and the pump. Perhaps this LSS will be of interest to fans of technical innovations and unusual devices, but the average consumer is unlikely.